|

|

Studies of

Run-to-failure, PM, and PdM programs have been conducted

over the years by several companies throughout the U S and

abroad.

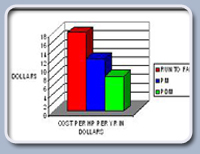

The graph shown

is typical of the savings realized with the implementation

of these programs. For example, if your plant used a total

of 1,000,000 horsepower you could expect a savings of about

$10,000,000.00 using a good PdM program over a

run-to-failure program and a $6,000,000.00 savings over PM

alone. |

|

|

PM/PdM PROGRAMS

Since inception, Wise

Air realized that in order to be a valuable maintenance organization

on the market, not only did we have to offer better service at a

very competitive rate, but we also had to be capable of offering a

more competent service that would greatly benefit our customer base

in the long run. Of course, compared to many other ambitious

but under funded organizations, we were lucky in the sense that we

at least had very solid internal expertise.

We invite all prospective customers to ask for further details about

our programs to see how they can benefit your plant. Ask

yourself how many companies would you have to hire to have the

following information at your fingertips. Motor Testing

and Analysis Vibration Testing and Analysis Oil

Testing and Analysis Thermography Testing and Analysis

Compressor Testing and Analysis, then ask yourself, how

knowledgeable in centrifugal compressors operations is this company.

Finally, compare the

quality of the information you receive from that vendor compared to

Wise Air, Inc. We think your choice will be clear and

WISE.

|

|

|